Background

This was a school project where the goal was to design and model in SolidWorks a collapsible cell phone stand that could be 3D printed. The backstory was that a company had hired you, the student, to design this stand as a give-away to customers who signed up for the mailing list at a trade show. The following constraints were given:

- It must fit within a boundary of 75x120x30 mm.

- It must use less than 4.0 cubic inches of model material.

- It must use less than 0.75 cubic inches of support material.

- It must incline the cell phone 65-70 degrees from the horizontal.

I also had some criteria in mind that would improve the usability of the cell phone stand once it was printed:

- It should cover as few ports or buttons as possible.

- It should accommodate a wide range of phones, including their cases.

- It should be thick enough at all points so that it can withstand everyday use without fear of breaking (I later chose 2 mm as the minimum value).

- It should have at least one large, flat surface so that the fictional company can add stickers or print on their logo or contact information.

Building the Model

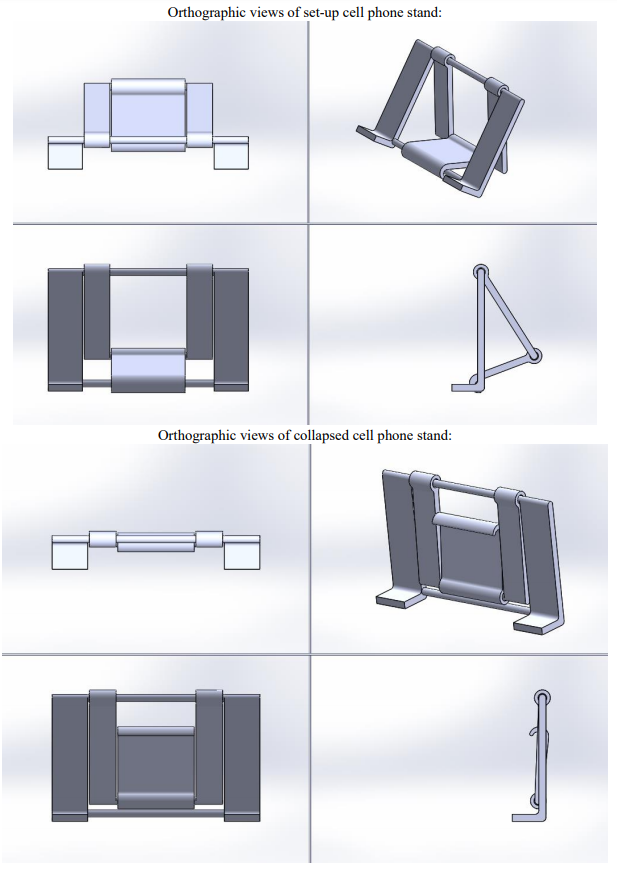

The first step to creating this was to sketch out a few ideas on a sheet of paper. I then used the design factors listed above to pick out the best design. From there, I made a rough dimension drawing so that I could start considering the geometry of it, and I could calculate the approximate weight, volume, center of mass, and angle from the horizontal. This process took the longest as I was constantly tweaking the dimensions to accommodate all the constraints and criteria. Finally, I created the model in SolidWorks, and made an assembly to test how the features fit together. There was a minor issue with the size of the hinges that required me to adjust some dimensions, but once I did, it was ready to go. I am pretty happy with how the final model turned out - I managed to meet all of the constraints, it is designed in a way that the size of the phone is not an issue, and it doesn't cover any buttons on my phone.

Results

When I received the 3D-printed stand, I was very pleased with how it turned out! After I had submitted my design to be printed, I was slightly worried that the center of mass was kind of high, maybe causing it to be prone to tipping over, but this is not a problem with the actual design. The weight of the phone is enough that when the stand is bumped or slid lightly, it doesn't tip over. It functions as I expected and it has no issues that I can find: it supports all phone sizes, it's fairly sturdy, and it meets all the requirements I originally set. This was a fun challenge and I would love to do more projects like it in the future!